In addition to traditional rigid printed circuit boards, many electronic devices rely on flexible PCBs due to their ability to bend and flex. Various industries, including consumer electronics, aerospace, defense, medical, industrial, automotive, and telecommunications, utilize flex and rigid-flex PCBs for their adaptability and space-saving properties. As electronic devices become increasingly compact, the circuit boards within them must also shrink in size. Flexible PCBs allow OEMs to efficiently integrate them into tight spaces within miniaturized devices.

Similar to standard PCBs, flexible PCBs can be single-, double-, or multi-layered, as well as single- or double-sided. However, in flex PCBs, each circuit layer is considered an individual PCB layer. Unlike rigid boards, flex PCBs are ultra-thin and highly flexible, typically ranging from 0.05 mm to 0.6 mm in thickness.

A standard four-layer flexible PCB consists of the following key components:

Core Layer – Made of polyimide (PI) material, commonly yellow, but also available in transparent, white, or black. Serves as the foundation of the flex PCB, with copper foil circuits on both sides.

Copper Foil Layer – Typically composed of rolled or annealed copper, providing high ductility and allowing repeated bending.

The copper foil is etched to form the required circuit patterns.

Standard copper thickness is 3 oz per layer.

In some cases, an adhesive layer is used to bond the copper foil to the core, which can reduce transparency and give the board a darker appearance.

Insulating Layer – A thin polyimide (PI) layer that separates copper circuit layers for electrical insulation.

The outermost insulating layers are known as coverlays, serving a function similar to solder masks in rigid PCBs.

Vias – Microvias or laser-drilled holes connect different copper layers. These vias are plated through to ensure electrical conductivity. Fabricators may use staggered or stacked Microvias to replicate blind and buried vias found in rigid PCBs.

Stiffeners – Reinforcement layers added at specific locations to provide mechanical support and ensure secure connections to connectors and system interfaces. Made from polyimide (PI), FR4, or stainless steel, depending on the application requirements.

This layered construction ensures that flexible PCBs maintain their reliability, durability, and adaptability across various industries while offering excellent electrical performance.

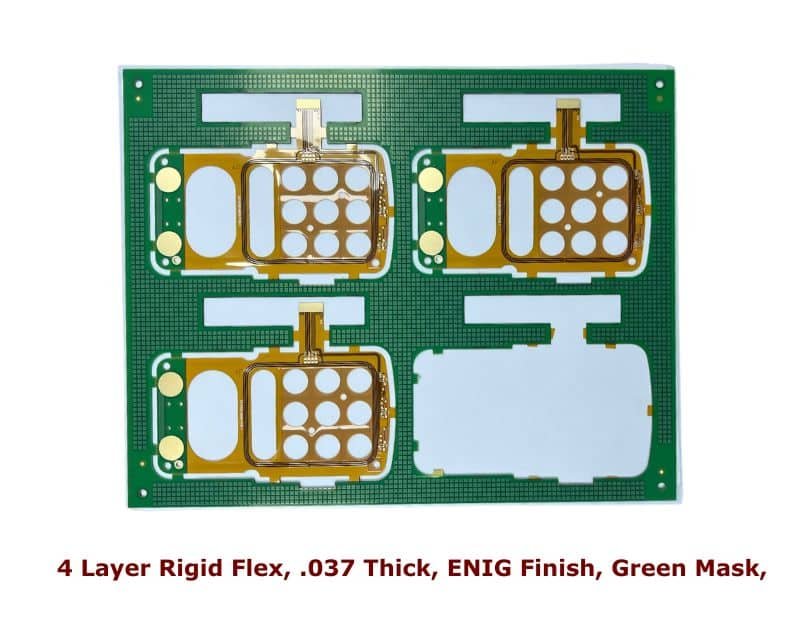

Modern rigid-flex PCB designs incorporate advanced shielding techniques to protect the flex areas from RF and EMI radiation. Depending on the application, some designs feature varying thicknesses between adjacent rigid sections, while others support asymmetrical constructions to meet specific design requirements.

With advancements in High-Density Interconnect (HDI) technology, flex and rigid-flex circuits can now achieve higher circuit densities than traditional PCBs. This allows for compact, high-performance electronic solutions that meet the evolving needs of industries such as aerospace, medical, automotive, and telecommunications.