The devices we use every day, from smartphones to washing machines, all rely on one crucial component: the printed circuit board (PCB). These electronic heartbeats make our technology function smoothly and efficiently. Imagine flipping a switch on your favorite gadget and, without a second thought, it turns on instantly. The magic behind that instantaneous response? A PCB.

At its core, a PCB serves as a common platform for electronic components. It connects them together, ensuring they communicate effectively while powering your devices.

Copper is the heart of PCB conductors. These metal traces carry electrical signals and power. Trace width is vital because it affects how much current a trace can handle. For example, a wider trace can carry more current but takes up more space. This balance is key for efficient design.

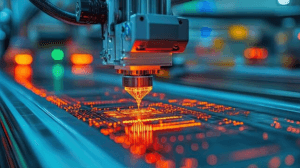

The foundation of every PCB design begins with schematic capture. This involves mapping out electronic circuits using specialized software. Accurate schematics are crucial, as they lay the foundation for the entire PCB. Popular design software includes:

Rigid PCBs are made from stiff materials for consistent support. Flexible PCBs, on the other hand, can bend and fold, ideal for tight spaces like in wearables. Each has its own set of advantages:

High-frequency PCBs are designed specifically for applications in telecommunications and high-speed electronics. These boards require careful consideration of factors like trace width and dielectric material to handle rapid signal transmission.

If traces are too close, it can lead to short circuits. Always ensure proper clearance for safety and performance.

Heat is a silent killer for PCBs. Poor design can lead to overheating, with studies showing that up to 35% of PCB failures are heat-related. Use thermal vias and appropriate materials to combat this issue.

Placing components carelessly can disrupt signal integrity. Best practices include:

Several software options streamline the design process. Each has unique features:

Once designed, essential tools include:

Many online platforms offer courses and tutorials, such as Coursera, Udemy, and dedicated maker communities. Engaging with these resources helps foster skills and knowledge.

In summary, PCBs are the backbone of modern electronics. Understanding their components, design process, types, and common pitfalls can empower enthusiasts and professionals alike.

Looking forward, trends like flexible circuits and 3D PCBs are on the rise, opening new possibilities in design and application.

Explore the fascinating world of PCB design and consider taking the first step in creating your own circuit boards. The future of electronics is in your hands!

© All Copyright 2025 by streampcb.com