PCB design errors can be costly. Mistakes in the early design stages can lead to delays, increased costs, and even product failure. Understanding how to design printed circuit boards (PCBs) with manufacturing and assembly in mind is crucial for engineers. The principles of Design for Manufacturing (DFM) and Design for Assembly (DFA) help ensure a smooth production process. This article outlines key strategies to optimize your PCB designs, reduce errors, and enhance overall efficiency.

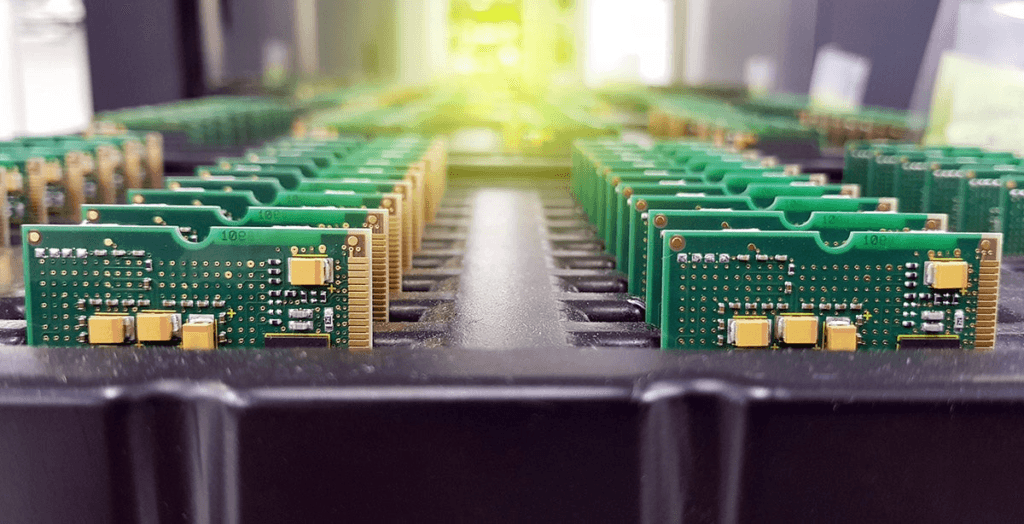

When designing PCBs, follow these essential DFM rules:

Real-world mistakes can be costly. For example, a misaligned component can lead to a short circuit, raising production costs significantly. Validating designs against common design rule checks (DRC) helps prevent these issues before reaching the factory floor.

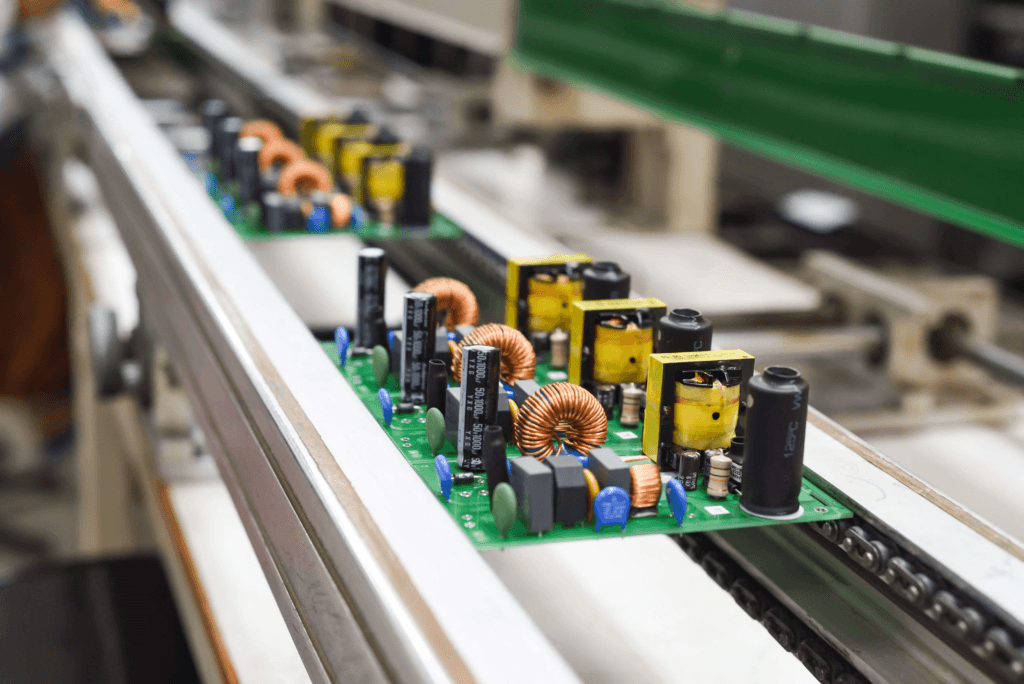

For SMT assembly, design with these factors in mind:

In THT, consider:

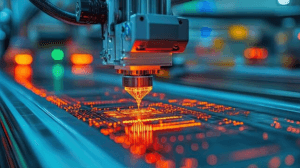

Automation streamlines assembly. Design for pick-and-place machines by avoiding complex geometric shapes. Simple, rectangular components enhance speed and accuracy.

Selecting the right substrate material impacts both performance and cost. Common materials include:

Use solder masks to protect traces and enhance aesthetics. Choose colors that contrast well with silkscreen markings for clear readability.

Material choices can affect both cost and reliability. For instance, while FR4 is cheaper, high-speed materials can offer better performance in demanding applications. Balancing cost with performance is essential, and comprehensive testing helps verify your choices.

Run design rule checks early and often. DRC helps catch errors before production, saving time and resources.

Create prototypes to test design assumptions. Refer to industry standards, like IPC-A-600, for guidance on acceptable quality levels. Testing with real-world conditions will uncover underlying issues.

Analyze failures when they happen. Common failure modes include delamination and open circuits. Learn from these failures to improve future designs, fostering a cycle of continuous improvement.

Clear communication with manufacturers is essential. Share your design intent and ask for feedback during the design phase to avoid miscommunication later.

Documenting your design clearly makes a big difference. Use standardized templates to ensure all necessary information is readily available. Include assembly instructions, testing requirements, and specifications.

Utilize a version control system for managing design revisions. This system helps track changes, ensuring both you and the manufacturer work from the latest design.

© All Copyright 2025 by streampcb.com