The success rate of product development is alarmingly low, with studies showing that up to 70% of new products fail. One major reason for this high failure rate is poor transitions from prototype to production. This article explores the prototype-to-production process in detail, focusing on challenges faced and effective solutions to ensure a smoother journey.

To create a successful prototype, it’s essential to set clear success metrics. These metrics help teams gauge whether their prototype meets expectations. Examples include:

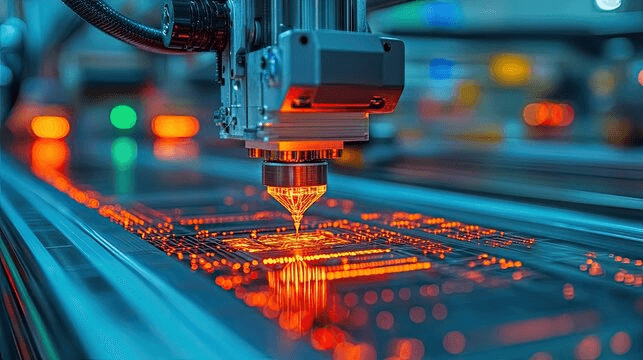

Transitioning from prototype to mass production presents unique challenges. It requires production lines, supply chains, and quality control measures to function seamlessly. A notable example is Apple, which successfully scaled its products through meticulous planning and a focus on supply chain management.

Choosing reliable suppliers is crucial. Material substitutions can lead to differences in quality and performance. Statistics reveal that 30% of manufacturers experienced supply chain disruptions in recent years, highlighting the importance of dependable sourcing strategies.

Different manufacturing techniques suit different products. Companies like Toyota utilize lean manufacturing to eliminate waste and improve efficiency. This approach not only reduces costs but also enhances product quality through streamlined processes.

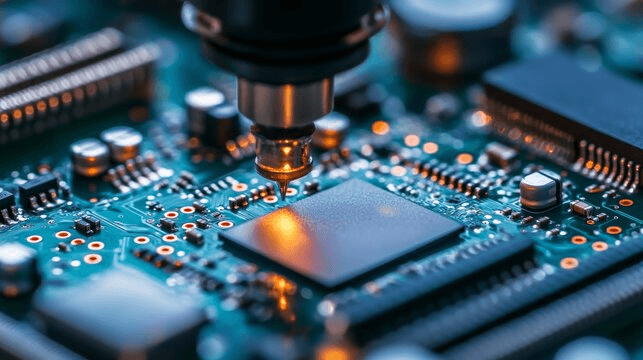

Rigorous testing is vital in the production phase. According to industry data, over 60% of product recalls occur due to quality issues. Effective testing processes can significantly reduce these risks, ensuring products meet safety and performance standards.

Automated testing tools can enhance efficiency and accuracy. For instance, tools like Selenium automate software testing, saving time and minimizing human error. Incorporating automation into testing can greatly improve the reliability of the final product.

Monitoring products post-launch is essential. Companies like Amazon collect feedback and analyze performance data to make continuous improvements. This feedback loop allows for adjustments and enhances customer satisfaction.

Accurate cost estimation is critical. Industry experts recommend involving all stakeholders in the budgeting process to create realistic figures. This practice helps avoid unexpected financial shortfalls during production.

Every project carries risks. Addressing potential issues early can prevent costly setbacks. Successful examples include Procter & Gamble, which employs extensive risk assessments and contingency planning to minimize disruptions during production.

Transitioning from prototype to production is fraught with challenges. By understanding common pitfalls and implementing effective solutions, teams can navigate this process more efficiently. Key strategies include setting clear metrics, optimizing processes, and utilizing robust testing methods. The future of prototype-to-production processes will increasingly rely on technology, creating opportunities for innovation and improved efficiency. Embracing these changes will pave the way for successful product development and market entry.

© All Copyright 2025 by streampcb.com