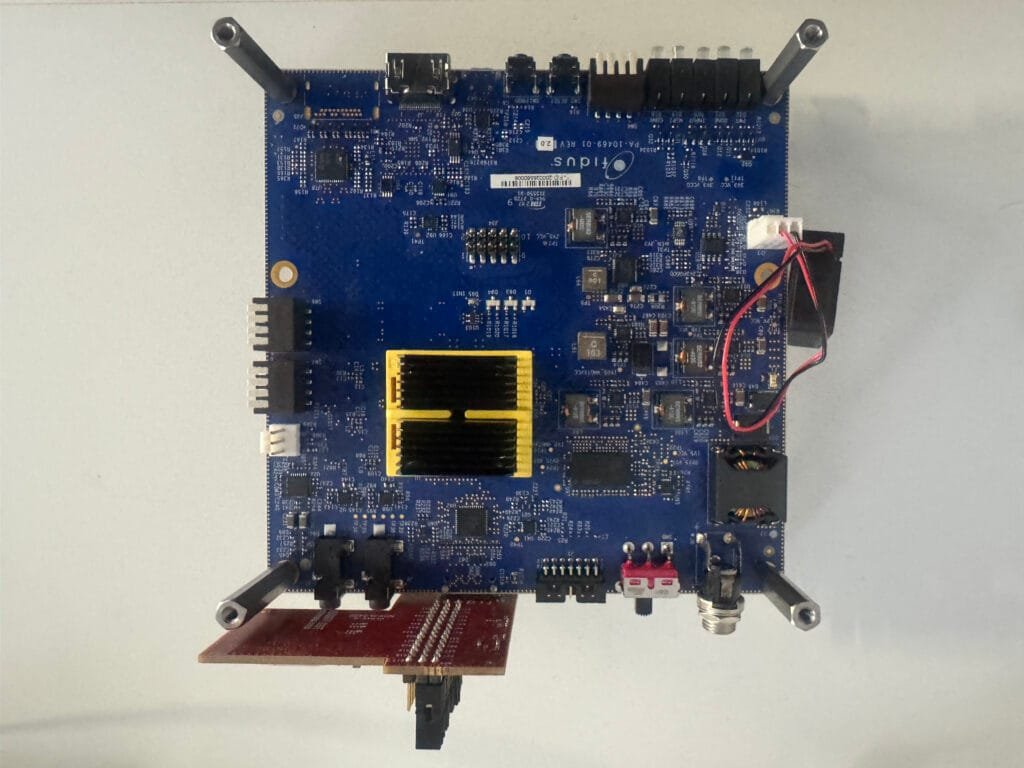

As PCBs grow in complexity, with more layers and advanced manufacturing processes, the importance of PCB assembly reliability has never been greater. A single PCB assembly can contain tens of thousands of soldered joints, and even one defective joint can lead to the failure of the entire board. Minor defects can compromise product performance in real-world applications, potentially triggering warranty claims, recalls, costly design revisions, and other operational challenges.

While functionality tests are essential for evaluating overall board performance, they may not fully capture the wear and tear a PCB assembly endures during use or when exposed to environmental stressors. Additionally, errors in process design, wave-soldering, or reflow-soldering can lead to product failures, emphasizing the need for robust quality assurance measures.

To minimize defects, manufacturers must prioritize quality from the earliest stages of the design process. By addressing potential quality, reliability, and thermal issues upfront, manufacturers can significantly enhance the performance and longevity of PCB assemblies.

Below, we delve into key technical insights, including common failures, challenges, and best practices, drawing from StreamPCB Inc.’s extensive experience with PCB assembly.

Monitor and control soldering temperatures to stay within component specifications.

With electronics becoming faster, smaller, and more complex, PCBAs require more power and this occasionally raises their operating temperature. Designing the PCB with an effective thermal performance is a critical factor, as more than half of all electronic components fail due to heat stress, a mismatch of CTE, or heat-induced material degradation. Some best practices we follow to address thermal considerations are:

Use thicker copper foil in PCB layer stacking or incorporate thermal vias for better heat dissipation.

Heat generation from high-power components.

PCB reliability testing ensures durability under environmental, electrical, and mechanical stress. It includes:

Functionality Tests

Reliability Tests

This ensures PCBs meet quality standards for reliable performance.

PCB failure analysis is the process of identifying and understanding the causes of failures. Failures can occur gradually, intermittently, or suddenly, and each case requires detailed investigation to determine the root cause.

Common PCB defects include:

Drilling Errors: Poor hole quality and breakouts.

During manufacturing, PCBs can experience:

Yes, PCBs can become contaminated during production due to:

© All Copyright 2025 by streampcb.com