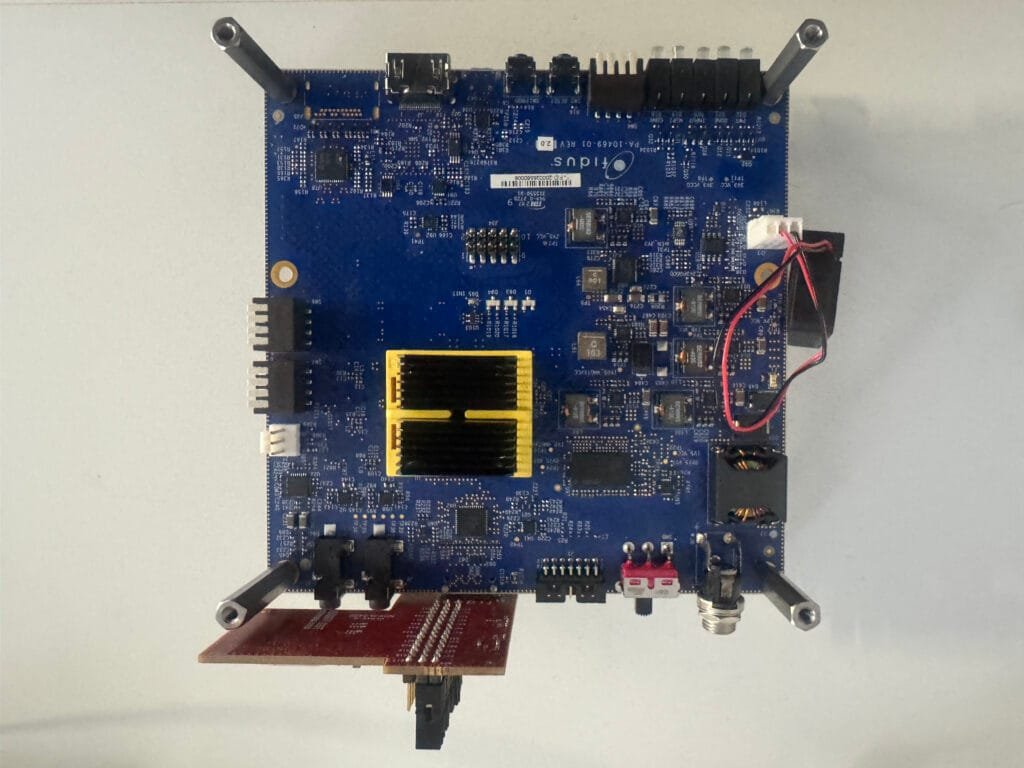

PCB circuit assemblies that incorporate both SMD (Surface Mount Device) and PTH (Plated Through-Hole) components demand careful handling, as each type requires distinct soldering methods.

SMDs can be attached to the PCB using reflow soldering, or they can be wave soldered.In the reflow process, solder paste is applied to the solder pads of the PCB using a stencil, and the SMDs are placed with their leads on top of the solder paste. Both the SMDs and the PCB are heated, reflowing (melting) the solder, and connecting the leads of the components to the solder pads on the PCB.

A wave of solder can be used to wave solder when connecting the SMDs to the PCB-Assembly. Instead of reflowing the solder paste, a wave of solder can be used. However, after the components are placed on the board, the board has to be turned over. To keep the components from falling off the PCB as it’s turned over for wave soldering, and having the wave of solder wash off any remaining SMDs, the SMDs first have to be glued in place onto the PCB.

When both SMT and pin-through-the-hole devices are used on the same assembly, several steps are needed for soldering.